Chemically cross-linked polyethylene foam is poised to revolutionize multiple industries with its remarkable properties and versatile applications. The future of this innovative material is bright, promising enhanced durability, sustainability, and groundbreaking uses across various sectors.

Advancements in chemical cross-linking techniques have significantly bolstered the durability and performance of polyethylene foam products. Through meticulous research and development, engineers have unlocked the potential to enhance the strength, resilience, and longevity of these foams, ensuring they can withstand the rigors of diverse environments and applications.

Moreover, the industry is witnessing a pivotal shift towards environmental sustainability in the production of chemically cross-linked polyethylene foam. By embracing eco-friendly cross-linking agents and processes, manufacturers are actively reducing the environmental impact associated with foam production, aligning with global efforts towards a greener future.

The most exciting aspect of chemically cross-linked polyethylene foam lies in its innovative applications across industries. From aerospace to automotive, packaging to medical, this material is finding new and unexpected uses, offering enhanced functionality and efficiency in ways previously unimaginable. Its adaptability and versatility make it a sought-after solution for companies looking to push the boundaries of what is possible.

Enhanced Durability and Performance

Chemically cross-linked polyethylene foam is revolutionizing the durability and performance standards in various industries. Through innovative advancements in cross-linking techniques, manufacturers are enhancing the strength, resilience, and longevity of polyethylene foam products. Imagine a material that can withstand the toughest conditions, providing unmatched durability and performance that outshines traditional foam materials.

Let’s take a short break from our article. Do not forget to review the following service pages of Durfoam:

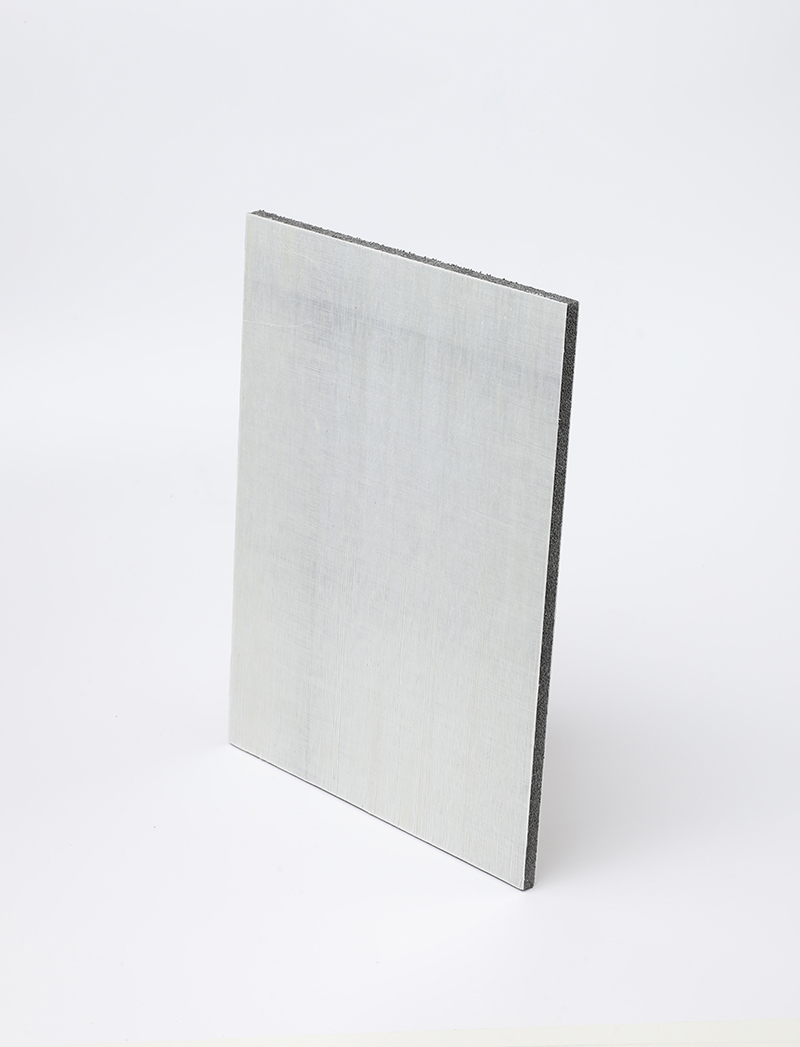

- physically cross linked polyethylene foam

- chemically cross linked polyethylene foam

- polyethylene foam

One of the key benefits of chemically cross-linked polyethylene foam is its ability to maintain its structural integrity even under extreme pressure or repetitive stress. This enhanced durability makes it ideal for applications where reliability is crucial, such as in protective packaging, cushioning materials, or insulation components. The foam’s improved performance ensures that it can withstand heavy loads without losing its shape or protective properties.

Moreover, the advancements in chemical cross-linking have paved the way for polyethylene foam products that offer superior impact resistance and shock absorption capabilities. This means that the foam can effectively cushion delicate items during transportation, absorb energy during impacts, and provide a reliable barrier against external forces. The enhanced performance of chemically cross-linked polyethylene foam opens up a world of possibilities for industries seeking reliable and long-lasting materials.

Environmental Sustainability

Environmental sustainability is a crucial aspect of the ongoing advancements in chemically cross-linked polyethylene foam. With a growing global focus on eco-conscious practices, the polyethylene foam industry is embracing innovative approaches to reduce its environmental footprint. One key area of progress is the adoption of eco-friendly cross-linking agents and processes, which play a significant role in minimizing the impact of production on the environment.

By shifting towards sustainable practices, manufacturers are not only meeting regulatory requirements but also contributing to a cleaner and greener future. The use of biodegradable or recyclable cross-linking agents is becoming more prevalent, ensuring that the end products are environmentally friendly and safe for disposal or recycling. This shift aligns with the broader industry trend towards circular economy principles, where materials are reused or recycled to reduce waste and promote sustainability.

Moreover, the development of energy-efficient manufacturing processes for chemically cross-linked polyethylene foam further enhances its environmental credentials. By optimizing production techniques and reducing energy consumption, manufacturers are able to lower their carbon footprint and overall environmental impact. This commitment to sustainability is not only a reflection of corporate responsibility but also a response to consumer demand for greener products.

Innovative Applications

When it comes to innovative applications, chemically cross-linked polyethylene foam is truly revolutionizing various industries. Imagine a material that can adapt to the demanding needs of aerospace, automotive, packaging, and medical sectors with remarkable efficiency and effectiveness. This foam, with its enhanced durability and performance, is becoming the go-to choice for cutting-edge applications where strength and resilience are crucial.

In the aerospace industry, chemically cross-linked polyethylene foam is being used to create lightweight yet incredibly strong components for aircraft and spacecraft. Its ability to withstand extreme conditions while remaining lightweight makes it an ideal material for improving fuel efficiency and overall performance in the skies.

Similarly, in the automotive sector, this foam is reshaping the way vehicles are designed and manufactured. From impact-absorbing bumpers to noise-reducing insulation, the innovative applications of cross-linked polyethylene foam are enhancing both safety and comfort for drivers and passengers alike.

Moreover, in the packaging industry, the versatility of this foam is being harnessed to protect delicate items during shipping and storage. Its cushioning properties ensure that fragile goods reach their destination intact, reducing waste and increasing customer satisfaction.

Lastly, in the medical field, chemically cross-linked polyethylene foam is playing a crucial role in the development of advanced prosthetics, orthopedic braces, and medical device packaging. Its biocompatibility and durability make it a preferred choice for applications where precision and reliability are paramount.

Overall, the innovative applications of chemically cross-linked polyethylene foam are pushing the boundaries of what is possible in various industries. As technology continues to advance, this versatile material is sure to find even more surprising and explosive uses, revolutionizing the way we live and work.